Right about now you're probably scratching your head and thinking "Well, I dunno, Lester, what in the hail is this Snowden feller doing right in the middle of this yere ampolifier blog or whatever this here Dougloid feller thinks it is?"

Good question. It's a phenomenon that I have decided to call the "Snowden effect" and it has, in fact, something to do with guitar amps and maybe bass amps as well.

Let me explain. One thing that we often see in this part of the world is this: someone appears, they've got a rare guitar amp from a long dead maker about which published information is scarce .When asked for technical details they say more or less-if they say anything at all-"Well, I'm sworn to silence because a friend of mine is tooling up to make these things, and he intends to charge an arm and a leg for them, you wouldn't want me to shank him now, would you? And don't think you can reverse engineer it either, because you'll never acquire the soul of tone that only I possess."

Classic cock tease.

Well, this is, like it or not, the age of information leakage, and if you want to keep something secret you can't go showing it off like a new Buick. Sooner or later the information gets out. A case in point is the amps made by an eccentric and marginally socialized guy named Alex (or Howard, come to think of it) Dumble. The secret was well and truly kept until two guys reverse engineered it by removing all the potting compound with dental picks and Dremels and documenting the whole thing. And in doing so they spawned a new industry of D-clones. Here's a site where the info's been collected.

Another prime example is the Standel 25L15, the innards of which were a closely guarded secret until somebody spilled the beans and Ted Weber, the Hoosier Speaker guru, came as close to reverse engineering it as anyone's likely to ever get. The schematic's not on the Weber site any more and they don't plan on offering any kits but the cat got out of the bag.

I also saw this phenomenon with the Fender Woody Princeton and lately an amp none of us were aware of, the National Professional. It does look tasty enough that I started a long term project file and I'll be out there slurping up every scrap of information I can lay hands on.

I do have an amp in transit, an Ampeg 7020, for which I know of no documentation. If it's got the schematic inside I'll publish it. Or maybe I'll just be a tease. No. It'll get published.

Never fear. "Murder will out, as we see day by day." So saith Geoffrey Chaucer, and it was as true then as it is now.

Wednesday, October 23, 2013

Saturday, October 19, 2013

Putting Harmony In Your Life: Reviving A Harmony H-322 Amp Part I.

The irrepressible Dirk Newton brought me this barn find amp he'd discovered on one of his sojourns, and after a while he decided he didn't want it as much as he wanted some folding money so it came my way. It's an interesting piece of single channel gear that sports volume, treble and bass controls, two fixed bias 7591 power tubes and four 8" Jensen 5w speakers. I'm always a sucker for oddballs and orphans so I was all in on this. The first task was to see if it passed signal and it did-barely-with a raft of junk tubes scrounged up around mi ranchito.

That all happened a while ago and today I decided to see what I'd acquired. The Mullard GZ34 rectifier tube will just about pay for this rascal.

Here are some images.The before and after stuff should be pretty clear, and the amp had had some significant bodging before I got there. The first task was to replace the electrolytic capacitors, rationalize the sorry excuse for a bias system, and replace whatever else came to mind. Constructing a bias board on some vulcanized fiberboard with eyelets and stuffing it with a diode, resistor and Fender style 10 k bias pot was no great task. It allowed me to dump the old fashioned selenium rectifier which was pretty much dead anyway. That's the funny looking gray thing next to the old pot.

There's also a mystery capacitor of 1.0 uf 100v value and I've got nothing like that in the shop and it doesn't show on the schematic so I may eliminate it and just continue building to print. The wax paper caps are gone and the amp's loaded with disc ceramic caps which are usually pretty reliable.

The power supply electrolytics were replaced with a single JJ 40-20-20-20 can and bracket mount. Thus required opening up the mounting hole with my $10 set of chassis punches from Harbor Freight which are now $25. They're still a bargain if you've priced Greenlee punches lately. They work fine on aluminum and mild steel.

After all this I noticed on the schematic that it has a provision for a 33 volt supply and that's something I have to add tomorrow. It dumps 33v DC into the tube filament section which I suppose is for noise reduction. Another oddity about this amp is that it had not one but two so called "death caps" and as I was installing a grounded power cord these went in the trash.

Powering up the chassis yielded an adjustable bias that got me the required 19 volts. After I got done rethinking the power supply, I realized last night that I hadn't grounded the JJ can, so doing that yielded 450v on the plates-much more like it. I hooked up the 33v power source but there's still some hum. I think some grounded inputs and 100 ohm resistors may take care a lot of it.

The power and output transformers are marked Transco, a brand I've never heard of unless it's the same Transco that makes neon sign transformers and sign ballasts.

I also incorporated a pair of 1 ohm resistors from the cathodes to ground so I'll be able to measure how much current the power tubes draw.

According to the Tung Sol data sheet a class AB pair of 7591s, fixed bias of about 20 volts and a plate voltage of about 350 volts should yield about 30w of power although I'm reserving judgment until power up time- I would be pleasantly surprised if this amp was capable of that kind of power.

The goal is to evaluate the amp before I spend too much time on the cabinet, which is pretty shabby looking at this time.

EDIT: I finished the power supply this morning and got a good solid set of voltages and a usable bias supply. A pair of matched 7591s and some tweaks and I'll be in business-it's a good sounding amp.

That all happened a while ago and today I decided to see what I'd acquired. The Mullard GZ34 rectifier tube will just about pay for this rascal.

Here are some images.The before and after stuff should be pretty clear, and the amp had had some significant bodging before I got there. The first task was to replace the electrolytic capacitors, rationalize the sorry excuse for a bias system, and replace whatever else came to mind. Constructing a bias board on some vulcanized fiberboard with eyelets and stuffing it with a diode, resistor and Fender style 10 k bias pot was no great task. It allowed me to dump the old fashioned selenium rectifier which was pretty much dead anyway. That's the funny looking gray thing next to the old pot.

There's also a mystery capacitor of 1.0 uf 100v value and I've got nothing like that in the shop and it doesn't show on the schematic so I may eliminate it and just continue building to print. The wax paper caps are gone and the amp's loaded with disc ceramic caps which are usually pretty reliable.

The power supply electrolytics were replaced with a single JJ 40-20-20-20 can and bracket mount. Thus required opening up the mounting hole with my $10 set of chassis punches from Harbor Freight which are now $25. They're still a bargain if you've priced Greenlee punches lately. They work fine on aluminum and mild steel.

After all this I noticed on the schematic that it has a provision for a 33 volt supply and that's something I have to add tomorrow. It dumps 33v DC into the tube filament section which I suppose is for noise reduction. Another oddity about this amp is that it had not one but two so called "death caps" and as I was installing a grounded power cord these went in the trash.

Powering up the chassis yielded an adjustable bias that got me the required 19 volts. After I got done rethinking the power supply, I realized last night that I hadn't grounded the JJ can, so doing that yielded 450v on the plates-much more like it. I hooked up the 33v power source but there's still some hum. I think some grounded inputs and 100 ohm resistors may take care a lot of it.

The power and output transformers are marked Transco, a brand I've never heard of unless it's the same Transco that makes neon sign transformers and sign ballasts.

I also incorporated a pair of 1 ohm resistors from the cathodes to ground so I'll be able to measure how much current the power tubes draw.

According to the Tung Sol data sheet a class AB pair of 7591s, fixed bias of about 20 volts and a plate voltage of about 350 volts should yield about 30w of power although I'm reserving judgment until power up time- I would be pleasantly surprised if this amp was capable of that kind of power.

The goal is to evaluate the amp before I spend too much time on the cabinet, which is pretty shabby looking at this time.

EDIT: I finished the power supply this morning and got a good solid set of voltages and a usable bias supply. A pair of matched 7591s and some tweaks and I'll be in business-it's a good sounding amp.

Thursday, October 17, 2013

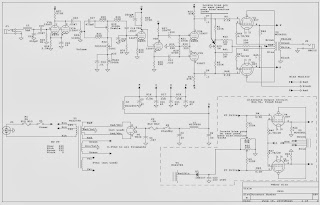

Biasing a VHT Pittbull 100w head.

Initially this VHT amp of Fryette design came in for a sudden loss of volume. Fixing that was easy as my Hickok 532 tube tester winkled out the shorted preamp tube in a matter of minutes.

However, after pulling the chassis and inspecting it for damage-always done with a new customer with an amp failure complaint-and measuring voltages I got down to checking the bias, and what I found was a 20ma mismatch and a 65 ma draw on some tubes-about twice the limit.

Finding out information on these amps is not that easy because they're relatively low production and not often seen in these parts. Fact is this is the first one I ever opened up. But nevermind. It seems pretty straightforward and well built, but there's not a lot of information to be had and I understand Fryette is very protective of their trade secrets. A request to their customer service people has, as yet, gone unanswered but if you read their website you'd conclude that biasing an amp is just one step short of launching the Space Shuttle.

It took a little research to locate the bias adjustment pot, and remember it's the one located underneath the tube board. That's right, screw driver in the hole and not the one that's some kind of line out pot. The picture on the Eurotubes page incorrectly identifies the line out pot as the bias trim pot. Don't you believe it. It fooled me too for a little bit.

Even with the level turned all the way down, it was still waaaaaay too hot and the mismatch wouldn't pass muster.

As I was waiting for a response from Fryette and consulting with a couple of savants, some basic knowledge of bias systems came to my aid. The AC from the power transformer bias winding goes through a single diode where it is rectified into DC, passes through a 47k 1w resistor, and then is sent on to the tube board to be distributed by the bias pot.

It seemed that if I wanted to raise the voltage and thus lower the bias current at the tubes, I'd have to reduce the value of the 47k resistor-in this case to 33k.

Once that was done and the second set of JJ EL34s was installed-the first was far too noisy-bias was at 20 ma on the lowest setting, so I ramped it up to a nice even 31 ma and that's where it stayed.

One point to remember. The standby switch should be in the II position when testing, and make sure the tube selector switch is properly set for the kind of tubes you're using-6L6GC or EL34.

UPDATE: As of November 8 the Fryette people have not responded to my request to supply information that I sent off to them. Not that I expected they would, mind you, but if you're in the market for an amp, you want the company to support it, right? Something to think about.

As usual, what you do with this information is solely your problem and your responsibility, not mine.

However, after pulling the chassis and inspecting it for damage-always done with a new customer with an amp failure complaint-and measuring voltages I got down to checking the bias, and what I found was a 20ma mismatch and a 65 ma draw on some tubes-about twice the limit.

Finding out information on these amps is not that easy because they're relatively low production and not often seen in these parts. Fact is this is the first one I ever opened up. But nevermind. It seems pretty straightforward and well built, but there's not a lot of information to be had and I understand Fryette is very protective of their trade secrets. A request to their customer service people has, as yet, gone unanswered but if you read their website you'd conclude that biasing an amp is just one step short of launching the Space Shuttle.

It took a little research to locate the bias adjustment pot, and remember it's the one located underneath the tube board. That's right, screw driver in the hole and not the one that's some kind of line out pot. The picture on the Eurotubes page incorrectly identifies the line out pot as the bias trim pot. Don't you believe it. It fooled me too for a little bit.

Even with the level turned all the way down, it was still waaaaaay too hot and the mismatch wouldn't pass muster.

As I was waiting for a response from Fryette and consulting with a couple of savants, some basic knowledge of bias systems came to my aid. The AC from the power transformer bias winding goes through a single diode where it is rectified into DC, passes through a 47k 1w resistor, and then is sent on to the tube board to be distributed by the bias pot.

It seemed that if I wanted to raise the voltage and thus lower the bias current at the tubes, I'd have to reduce the value of the 47k resistor-in this case to 33k.

Once that was done and the second set of JJ EL34s was installed-the first was far too noisy-bias was at 20 ma on the lowest setting, so I ramped it up to a nice even 31 ma and that's where it stayed.

One point to remember. The standby switch should be in the II position when testing, and make sure the tube selector switch is properly set for the kind of tubes you're using-6L6GC or EL34.

UPDATE: As of November 8 the Fryette people have not responded to my request to supply information that I sent off to them. Not that I expected they would, mind you, but if you're in the market for an amp, you want the company to support it, right? Something to think about.

As usual, what you do with this information is solely your problem and your responsibility, not mine.

Wednesday, October 9, 2013

Biasing a Peavey 5150

The Peavey 5150 is another in a series of high gain amps beloved of metalheads and I rarely see them, because the owners are mostly not about tone. This once came in because all it would produce was a loud groan when powered up.

A little investigation revealed that one of the brand new preamp tubes was shorted so that got replaced in short order and I got sound but not muscle. A little more investigation revealed that the number 4 power tube had no screen voltage. So out came the tube board and all four screen resistors got replaced with some 220s rather than 100 ohm units, because that's what I had, and if 470s were good enough for Leo then......... It's worth noting that a plug lies right on top of #1 so you can't get at it with a multimeter probe but nevermind. This is a good time to check everything on the back side of the tube board, including the two flyback diodes.

Although this amp is fixed bias, it's nonadjustable in the stock configuration, the level being set by R68 which used to occupy the space in the picture. It's mounted parallel to the adjacent electrolytic capacitor. And they're usually biased way too cold.

A short digression.

In a guitar or bass amp "bias" refers to bias voltage, which is a negative voltage applied to the grid. This sets the operating level for the tube. Bias voltage can be obtained in two ways. In a fixed bias arrangement, the negative voltage is supplied by an external source such as a dedicated transformer winding. Even if there's no adjustment feature it is still fixed bias, and if it's adjustable like we did here it's still fixed bias. The other ways is cathode bias, which uses a cathode resistor to accomplish a similar purpose by raising the cathode above ground potential. We don't have that here, and it is less efficient, more touch sensitive, and usually used in lower power amps.

To improve function it is necessary to incorporate an adjustment pot. I had a Bourns 10k pot that you see here. On one leg I attach a suitable resistor-in this place an 8.2k 1/2 w. number and cut a piece of spaghetti tubing to insulate the lead.. I take the center pin of the pot and wrap it around the unoccupied other pin and secure it with a dab of Mr. Kester's best solder. Then I wrap about an inch or so of wire around the pin with some spaghetti covering and solder it in place.

To finish up the job, I set the resistance with a multimeter to about 15k as a good starting place, and then wrap the end of the two leads around either side of the capacitor and solder them in place.

Then I stick the Bourns pot down with a dab of superglue. Don't go crazy, you might need to remove it some day.

The next thing to do is fire the amp up with any good bias probe installed and flip the standby switch to on. If things start going sour shut down and do a rethink. But if you've got it right you should see about 25ma per tube.

Then it's a simple matter of measuring plate voltage and using the Weber bias calculator to find the right level you want. If they're new tubes always leave a little room for drift. At 481v on the plates I set it to about 34 ma on the hottest tube.

Tuesday, October 1, 2013

Biasing a Blackstar HT100

This amp arrived for a basic tube checking and rebiasing after three years of heavy service three nights a week. A couple preamp tubes were pretty well shot but the power tubes were fine. When I went to check them with my handy dandy cathode current checkers I found no cathode current but -95 volts on the grids. Whaaaaaaa?

Bear in mind that Blackstar don't think you or I know nuthin' bout these yere ampolifires, Lester. You either Jeeter. We've had this conversation before.

Doing a little research I discovered a reference to the fact that something must be plugged into the input jack to make things happen. It seems that with nothing in the input the amp acts as if it is on standby. I can't think of a reason for that unless you want to make people think that the amp is a lot quieter than it really is.

Once that was done the cathode current came up nicely on my two Harbor Freight dedicated multimeters. The procedure then is to adjust the bias balance control marked PR1-which is the upper one in the picture-to equalize the bias current and then adjust the level with PR2 which is the one in the bottom of the picture. These pics were taken from the rear of the amplifier.

As I understand it the HT60 is adjusted the same way.

Now you know.

Subscribe to:

Posts (Atom)